Knock sensors

The main function of the knock sensor is to sense vibrations causeway engine knock or detonation. Correct functioning of this sensor, helps save the engine.

- Full assembly and electrical compatibility.

- OE-compliant sensitivity.

- Anti-corrosion properties to extend the life of the sensor.

OTHER IN THIS CATEGORY

OE measurement accuracy. Full compatibility with ECU. Increased durability of the measuring system - thermoanemometer.

Full ECU-adaptation compatibility. Factory airflows. Increased wear resistance - improved throttle bearing.

Available as fuel feed units or as fuel pumps. 100% geometric and electrical compatibility. OE pressure and fuel flow. Reinforced, fuel resistant structure. Factory preset fuel pressures and pump output. More durable seals.

Wide range applications. Increased oil and heat resistance. Seals and mounting kits included. Full geometric compatibility ensuring 100% sealing.

Enhanced mechanical resistance. Factory capacity. Assembly completeness.

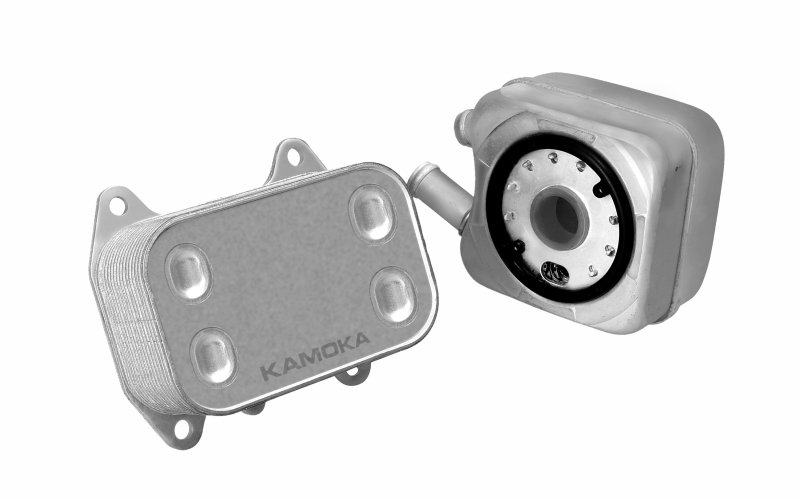

Optimized flow channels. Easy installation thanks to OE compliance. High pressure impulse tested (up to 10 bar). Automated heat sink bonding process minimizing the possibility of leakage. Full dimensional compatibility. Resistance to vibration and pressure surges. Extended durability through the use of corrosion-resistant materials.

Full electrical compatibility to ensure adaptability. High operating accuracy to ensure constant idle speed. Full geometric compatibility.

I ncreased resistance to oxidation. OE quality to guarantee correct measurement. Flexibility to prevent measure breakage.

Integrated anti-twist protection. Enhanced oil and heat resistance of seals. Excellent leakage protection against dirt penetration into the engine and oil leakage.

High corrosion resistance. No pressure loss due to optimized design. Highest oil separation efficiency.

Factory ratio characteristics. Full compatibility with ECU. Increased resistance to weather and continuous movement.

Highest thread precision. Dimensional stability. OE compliant tightening characteristics (plastic deformation/tightening moments).

The camshaft position sensor allows correct engine control. Thanks to the high quality KAMOKA sensors. the engine starts correctly and reaches nominal power. Full geometric compatibility to facilitate installation and guarantee proper distance from the crown wheel. Guarantee of correct engine operation. Increased durability due to increased tightness.

These sensors help determine the position of the crankshaft. Their main function determines the proper work of the engine. Excellent geometric fit, facilitating installation. Ensuring proper operation of the motor. High durability and resistance to interference.

Increased measurement precision. Increased resistance to high temperatures and oil. Precision machining guarantees tightness of connections.

Increased durability thanks to increased resistance to wear, temperature and oil. Effective vibration damping - reduction of engine vibration and noise. Properly selected stiffness - engine stability without excessive vibration transfer.

Stable operation under high pressure and temperature conditions. Resistance to vibrations and electromagnetic interference. Accurate fuel pressure control.

Full compatibility with OEM installation. Insulation resistant to temperature and moisture. Durability under intense vibrations.

Complete collectors also with flap sets. Increased mechanical resistance (vibration, temperature). Factory-made shapes and cross-sections guaranteed to work with ECU.

ECU-compatible opening characteristics. Increased resistance to moisture. Enhanced mechanical resistance of the opening mechanism.

Contain all necessary elements for full refurbishment (including gaskets). Components resistant to temperature and pressure. Easy installation according to OEM standards.

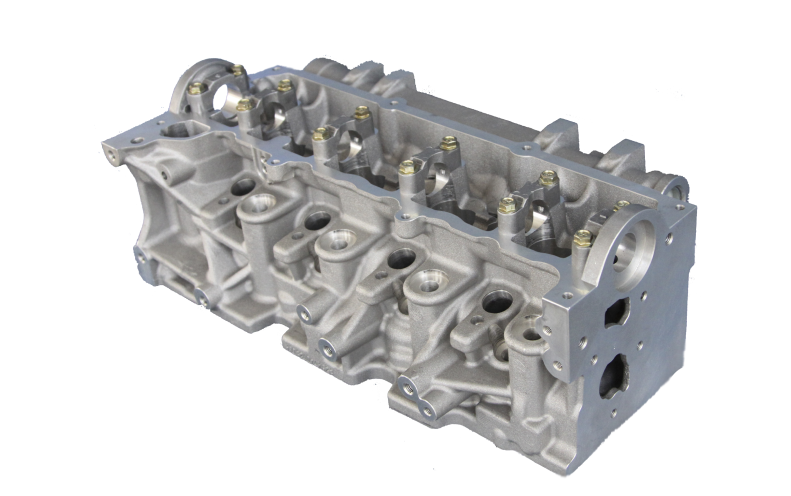

Resistant to high operating temperatures and pressures. Precision machining of valve seats and guides. Solid construction made of lightweight alloys.

OE-compatible mechanical processing. Enhanced mechanical resistance. Factory-applied cam profile.