Brackets

- Homogeneous homogeneous structure for adequate mechanical strength.

- Factory geometric dimensions in accordance with OE.

OTHER IN THIS CATEGORY

Individually tailored friction compound for pad application. Quiet operation thanks to bevelled friction surface or antivibration pads. Friction compound to reduce dust. Increased rigidity of the steel backing plate.

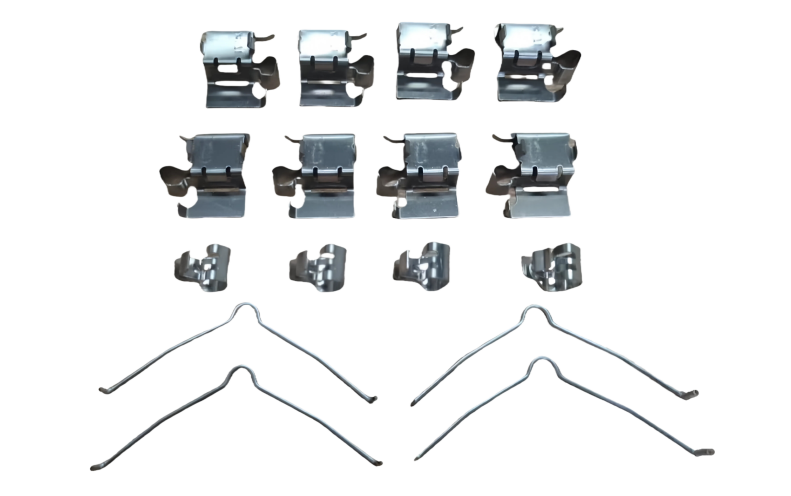

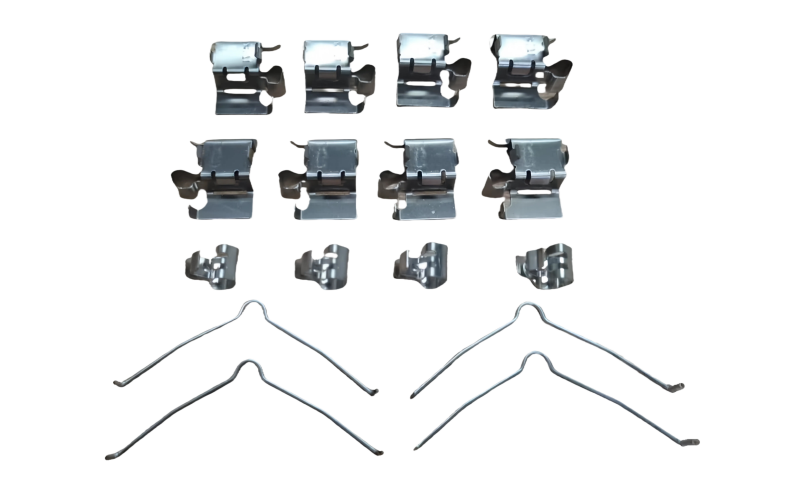

High mechanical strength – safe and durable mounting. Corrosion resistance – components protected with anti-corrosion coating. Dimensional accuracy – ensures proper fit.

High mechanical strength – safe and durable mounting. Corrosion resistance – components protected with anti-corrosion coating. Dimensional accuracy – ensures proper fit.

Customized friction compound for jaw application. Quiet operation due to bevelled friction surface.I5 Friction compound to reduce dust. Increased corrosion resistance of bearing elements. Also available in sets with mounting accessories and brake cylinders.

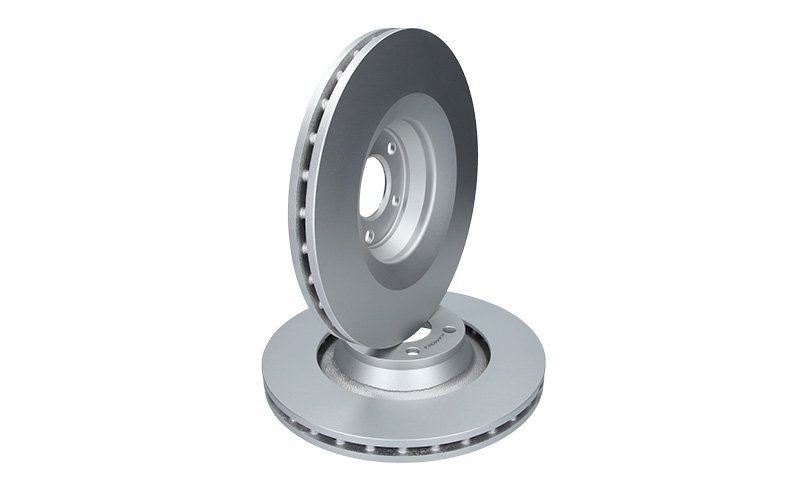

We use high quality ductile cast iron with multi-metallic anticorrosion coat subjected to a hardening and temping process while in production. Our disc has ribs and air channels useful for reducing weight and dissipating heat while braking. Anti-corrosive multimetal coating to protect the entire disc from corrosion. Highest quality cast iron used during production. Multi-stage quality control after each brake disc machining process. Compliance with OE braking process parameters. Quiet and vibration-free operation.

Multimetal corrosion protection coating. Friction surface treatment to level out drum runout. Homogeneous material structure to increase resistance and improve mechanical properties.

KAMOKA offers high quality brake calipers without any return requirement. It can have an electrical handbrake. We also offer hydraulic wheel cylinders. Reinforced parking brake mechanisms. Multi-stage seals for electric parking brake mechanisms. Hardened brake pistons. Durability of seals. No deposit and the need to return a damaged caliper.

Easy and quick repair without removing the clamp. Improved seal design for longer system life. Availability of different motors dedicated to different types of brake systems.

Compatibility with OE of the material from which the brake disc covers are made. Anti-corrosion coating to increase durability. Manufacturing technology that accurately reproduces the shapes and ribs to enable, for example, ventilation of the friction linings.

Improved seals for increased durability. Heat-treated pistons. Multi-stage leakage control at the production stage. High flexibility of dust shields.

We offer complete brake shoes mounting kits to wide range of vehicles. Dimensional compatibility with OE, Trouble-free installation, Guarantee of correct operation of the system.

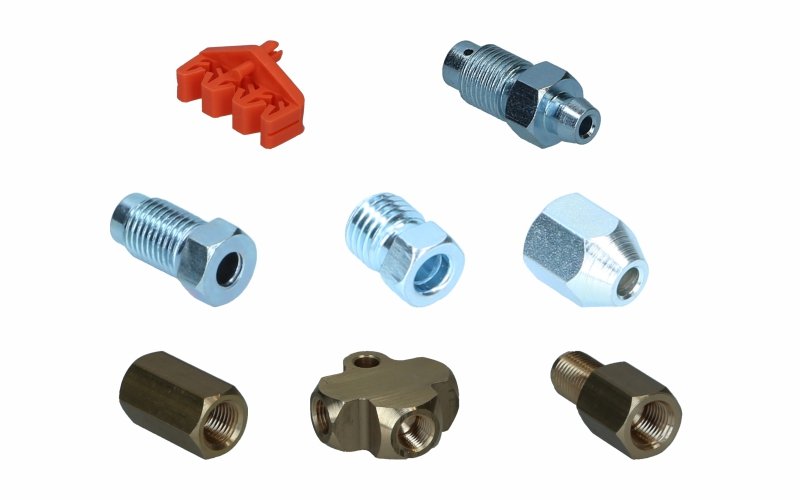

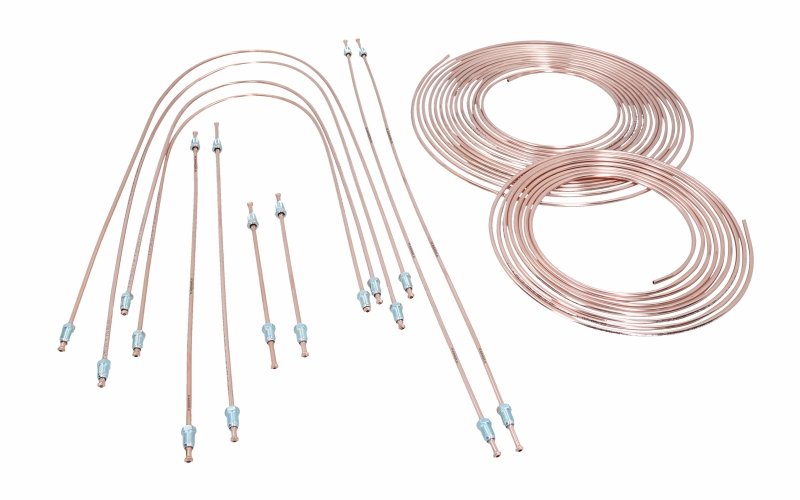

A full range of normals and tools for the preparation of universal pipes (connectors, reductions, tees, vents, fixings, cutters, pipe benders and deburrers, as well as a device for swelling pipes).

KAMOKA offers durable and reliable brake pad wear sensors to help insure optimal safety for the vehicle. These sensors may be offered as in whole brake pad sets or may be presented as separate parts. Accuracy of manufacturing for easy installation. Full electrical compatibility with vehicle installation. Accuracy of measurement in accordance with OE.

KAMOKA offers easy-to-install and durable ABS sensors. Our offer includes, passive sensors (for older cars) and currently used active sensors. High accuracy of speed measurement - even 0.1 km/h. Full electrical compatibility with the vehicle's electrical system. Accuracy of manufacture ensuring trouble-free installation and proper seating which is a requirement for correct measurement.

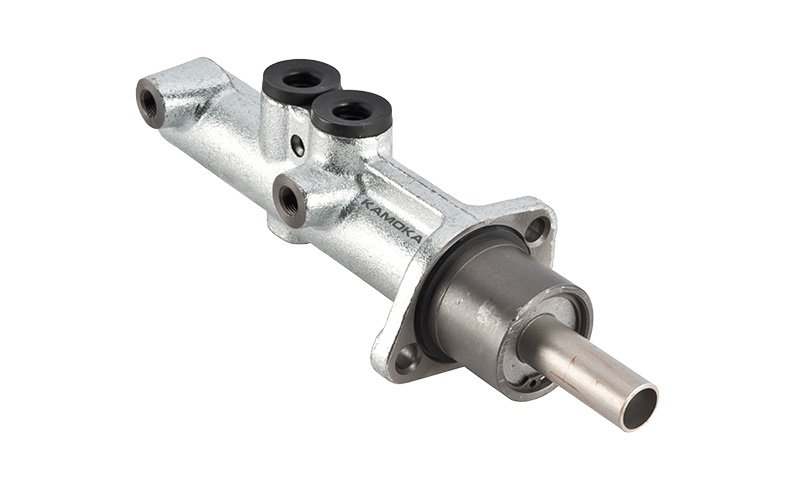

Master cylinder is a control device that converts non-hydraulic into hydraulic pressure. In offer we have ported tandem and portless master cylinders. Hardened piston rods. Reinforced sealing. Hydraulic ratio compatible with the factory.

High flexibility – adaptation to the work of wheels and suspension without restrictions in fluid flow. Durable, highly resistant to brake fluid material. Perfect matching of connectors and lenghts for easy installation.

The offer includes ready-to-install cables and universal cables to be prepared. Increased resistance to corrosion. Easy to profile brake lines. Full spectrum of brake lines in a coil, even for the most demanding vehicles and weather conditions – (copper, copper-nickel and steel wires in a pvp sheath- the equivalent of first assembly brake lines).