Electric water pumps

- Rapid engine heating.

- Multistage control of leakage and pumping parameters.

- Increased resistance to high temperature and coolant pressure.

- Completeness of normals needed for proper installation.

- Compatibility with all available coolants.

- Additional moisture insulation of the pump driver for longer system life.

OTHER IN THIS CATEGORY

The KAMOKA range includes mechanical and electric water pumps with seals and long-life bearings. KAMOKA water pumps have the same water flow as the original ones. Depending on the type, they have cast impellers made of metal or plastic. High-quality bearings and a housing designed using CFD technology guarantee quiet operation, optimal coolant flow and temperature stability of the engine. • Refined internal cross sections and rotors to reduce cavitation. • Increased bearing life. • OE-compliant discharge and pressure. • Completeness of seals.

Thermostats are the element of the engine that control the cooling system. Our offer includes both typical mechanical thermostats and electronically controlled thermostats. Rapid motor heating. Tested opening/closing temperature. Increased resistance to high temperature and coolant pressure. Completeness of normals needed for proper installation. Compatibility with all available coolants.

KAMOKA offer includes viscous and electronically controlled fan clutches. Those clutches are quite and maintenance-free. On and off temperature in accordance with OE. Application-adapted viscous oil. Gear ratio to ensure adequate airflow through the radiator in accordance with OE.

Enhanced thermal and mechanical properties. Pressure-tested mechanical properties. Durable transparent plastic for easy control of fluid quantity.

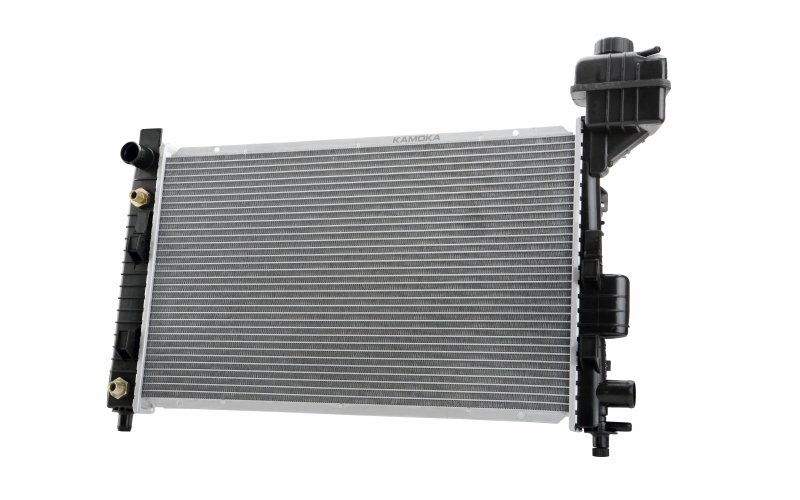

Extended life due to the use of corrosion resistant materials. 100% dimensional compatibility. Resistant to vibration and pressure strokes. Multi-step quality control. High thermal efficiency according to OE.

Dedicated solutions with factory performance. Available as assemblies as well as fans alone without housings. Quiet by using computer analysis during design and balancing.

Conforms to OE geometric dimensions. Improved seals to increase sensor life. Full electrical and connection compatibility.

Multi-stage tested quality to guarantee correct motor operation. Thermal safety of the motor. High quality and geometric compatibility to facilitate installation and improve joint tightness.

100% geometric and electrical compatibility. Multi-stage sensor operation control. Guaranteed safety of engine operation.

Always comes with the seals you need. Reinforced oxidation- and heat-resistant design. Optimized materials for thermal expansion.

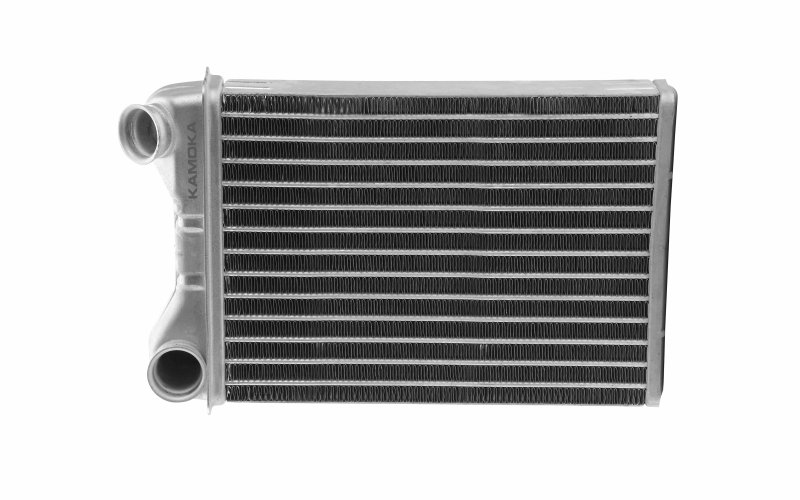

High thermal efficiency according to OE. Resistant to vibration, corrosion and pressure. Multi-step tightness control reduces the risk of unpleasant odour in the vehicle cabin. Easy installation thanks to oe compliance.

Factory control characteristics. Increased durability with heat sinks. Full electrical compatibility.

Factory performance guaranteed to work with automatic air conditioning systems. Quietness. Easy installation.

Guarantee of correct pressure in the system thanks to precise valves in the plugs. Resistance to high temperatures and temperature changes thanks to the material used. Full compatibility with original expansion tanks.

Complete assembly for faster replacement. Resistance to vibration and pressure changes. Full dimensional compliance. Extended durability thanks to the use of corrosion-resistant materials.