Drivetrain

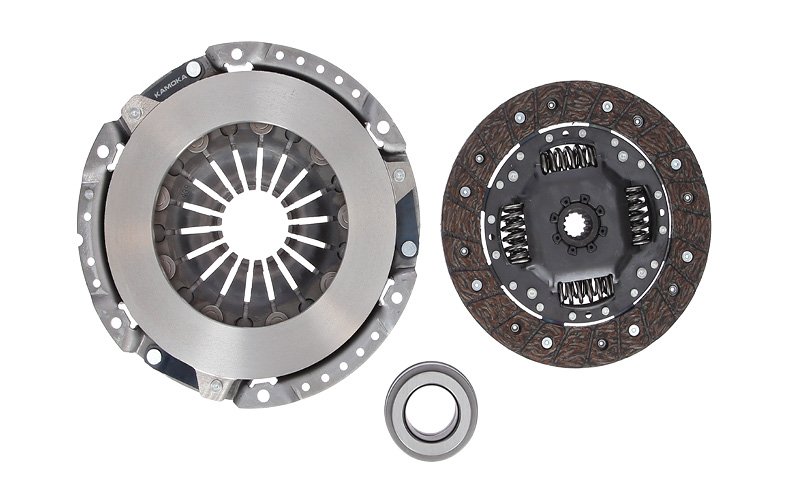

A mechanical device which engages and disengages the power transmission. We offer...

A mechanical device which engages and disengages the power transmission. We offer clutch discs with simple torsion damper and with multi-stage dampers through rigid clutch discs for use in the dual mass flywheel right through to the displacement correction clutch disc.

The clutch slave cylinder allows the clutch disc to move in order to operate the...

The clutch slave cylinder allows the clutch disc to move in order to operate the clutch. This solution has lower weight, higher reliability and greater durability than the traditional system of a bearing, fork and rollers. Out clutch slave cylinder has high-quality seals and meet the same standards as the original.

Wheel hubs are fastened to the car's wheels. They can rotate freely thanks to...

Wheel hubs are fastened to the car's wheels. They can rotate freely thanks to the bearings inside the wheel hubs. Their condition is important for the performance and safety of the car. Our wheel hub has high-quality, long-life seals and bearings. Those bearings may be replaceable.

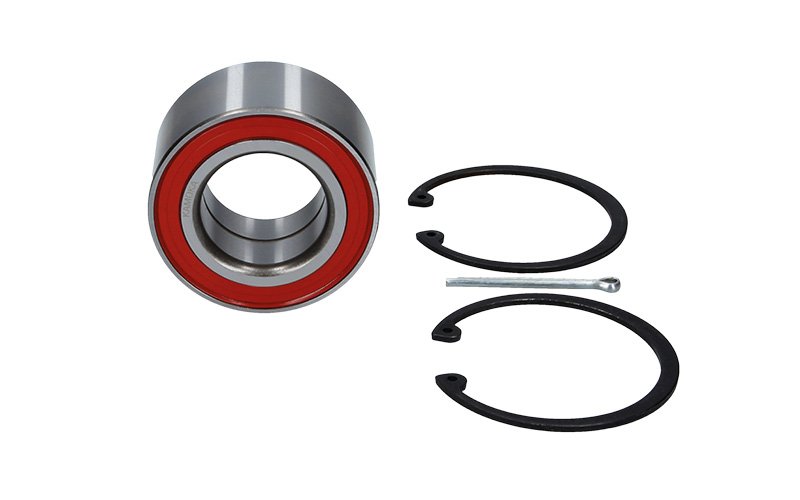

A wheel bearing is a set of steel balls held together by a metal ring call a race....

A wheel bearing is a set of steel balls held together by a metal ring call a race. They help wheels spin fast with as little friction as possible. KAMOKA offers complete wheel bearing sets including all necessary parts.

Constant-velocity joints transmit power through a variable angle, but at constant...

Constant-velocity joints transmit power through a variable angle, but at constant rotational speed. There is no significant increase in friction or backlash. Our CV joints have hardened transferring torque surfaces and elastic, temperature resistant boots. Our kits include also grease.

We offer a very elastic and weather resistant CV joint boot kit. They are needed...

We offer a very elastic and weather resistant CV joint boot kit. They are needed when a used CV joint begins to deteriorate at the axle joint and driveshaft due to water exposure. Kits include grease and two clamps that are designed to be tightened without the use of special tools.